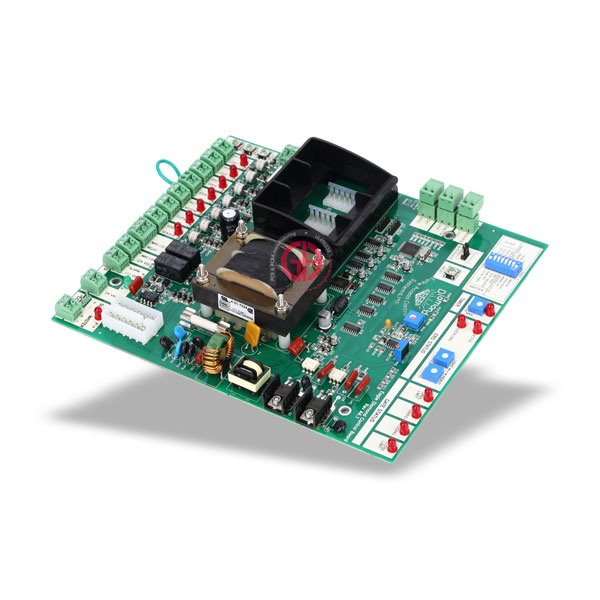

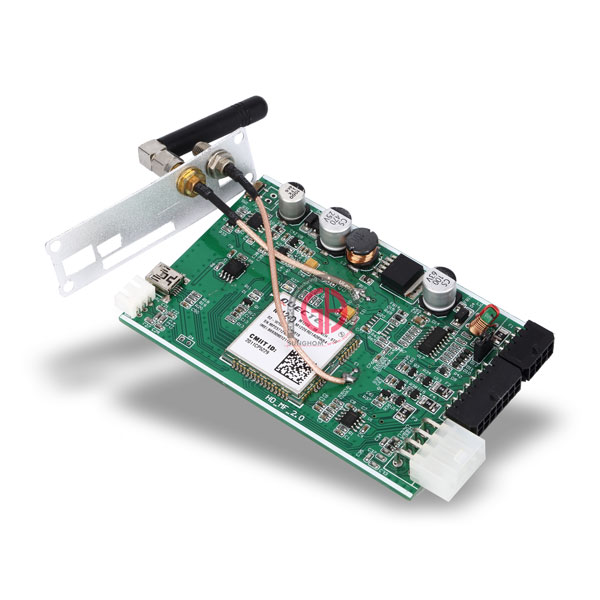

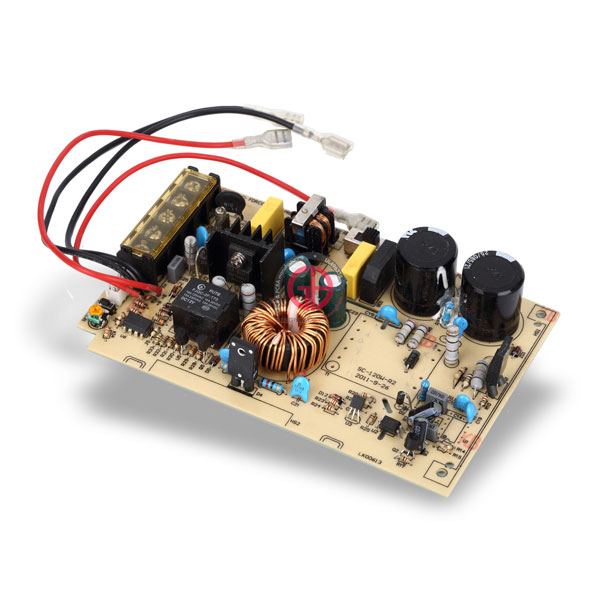

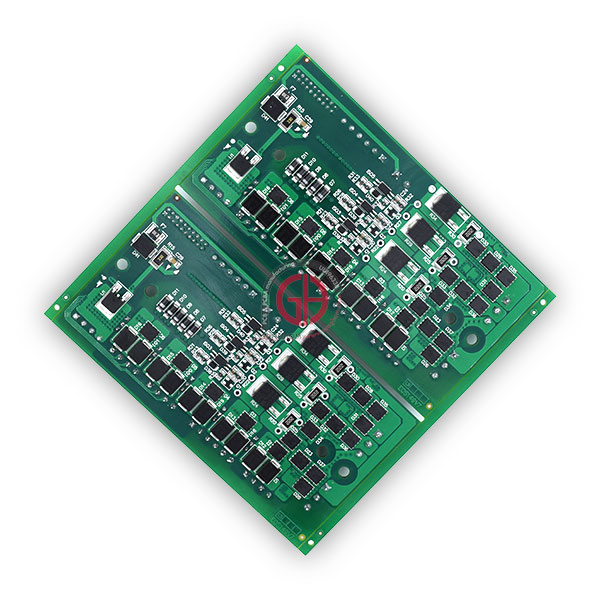

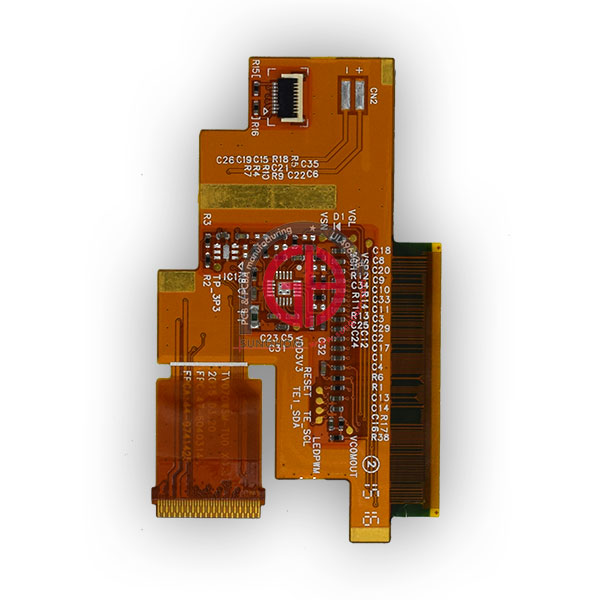

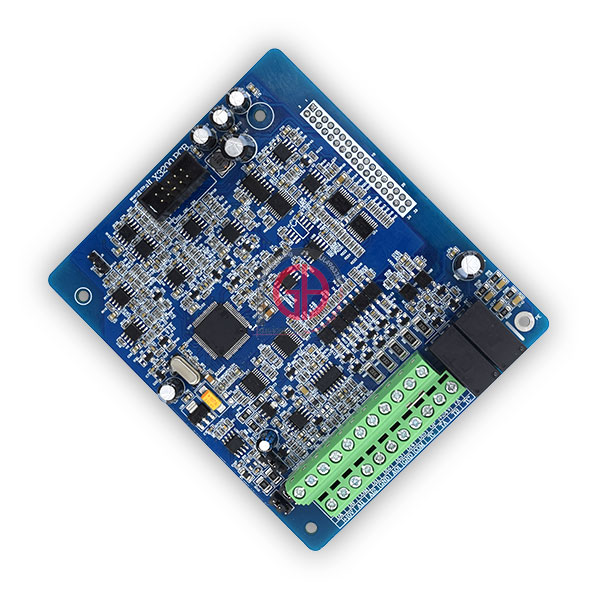

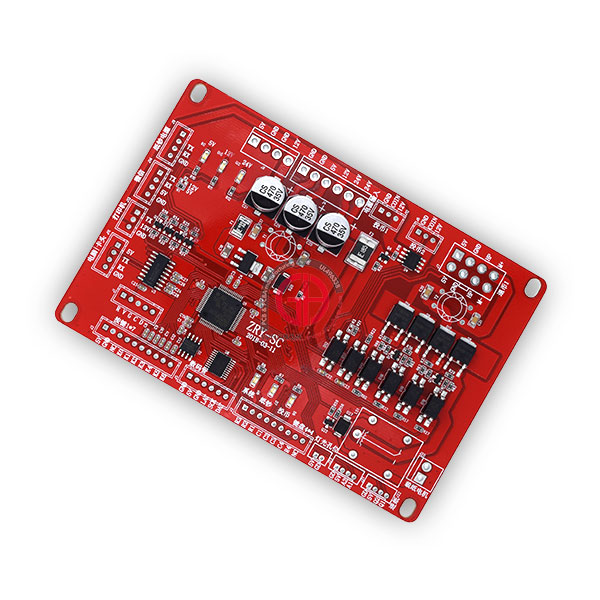

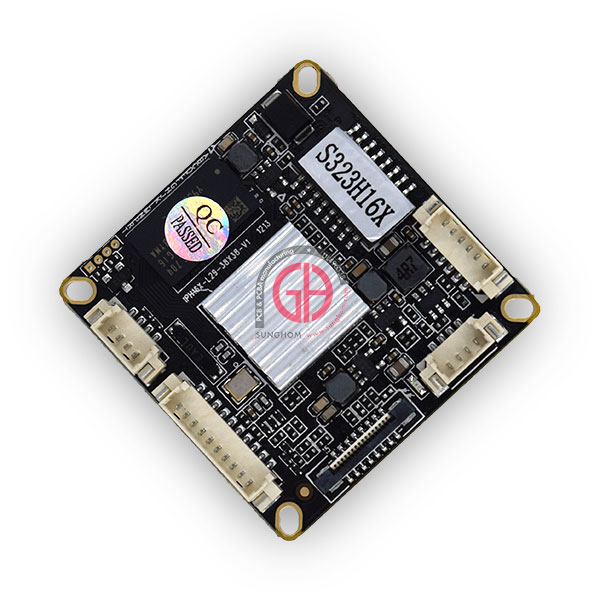

SUNGHOM offers full Turn-Key and partial Turn-Key PCB Assembly Services.

In Full Turn-Key, we handle everything including making circuit boards, ordering components, quality inspection and final assembly. In partial Turn-Key, you can order the PCBs and partial components, we will fix the remaining parts for you. BOM must include the quantities, reference designators, and manufacturer name, part number.

Various testing method will be applied to the assembled boards before the final shipment.

SUNGHOM’s production facilities are ISO9001 certified to ensure we go beyond your expectations.

| No. | Item | Capacity |

|---|---|---|

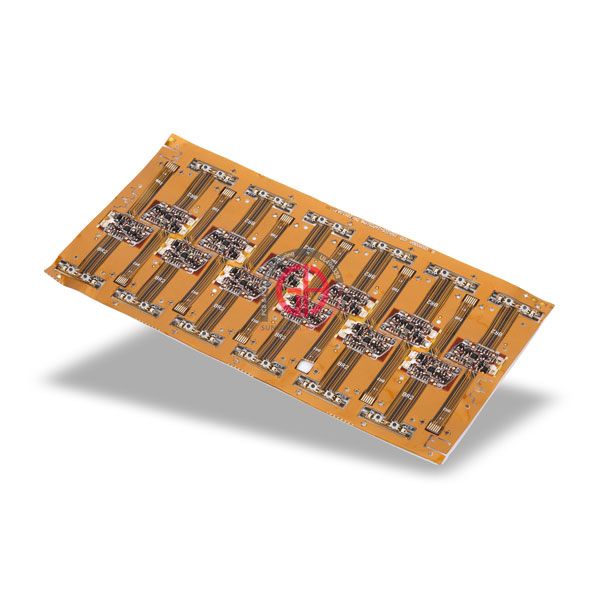

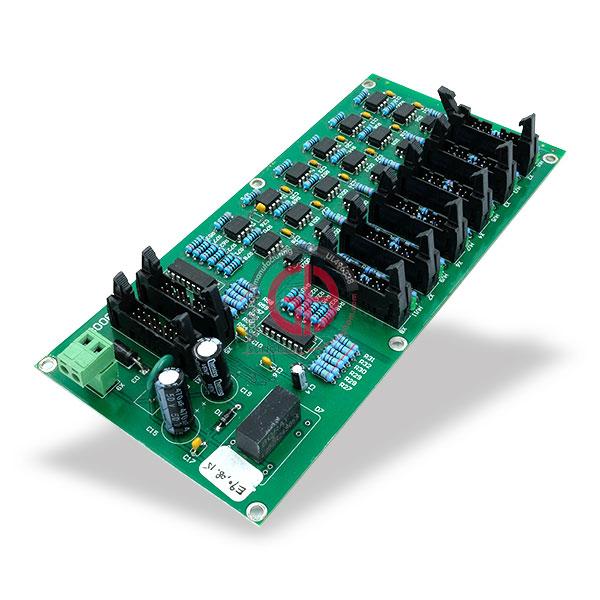

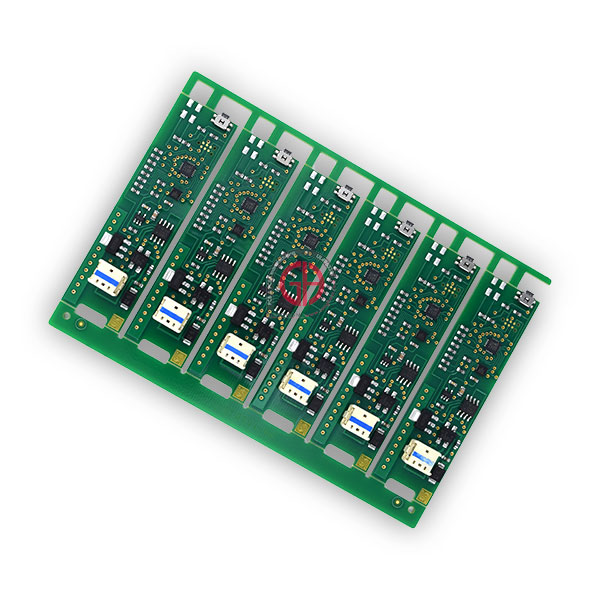

| 1 | Assembly Type | THD (Thru-Hole Device) SMT (Surface-Mount Technology) SMT & THD mixed 2 sided SMT and THD assembly |

| 2 | Order Quantity | Protytpe, Medium, Mass Production |

| 3 | Parts | Passives parts, smallest size 0201 Fine pitch to 8 Mils BGA, uBGA, QFN,POP and Leadless chips Connectors and terminals |

| 4 | Component Package | Reels Cut tape Tube and tray Loose parts and bulk |

| 5 | PCB dimensions | Smallest size: 5*5mm Largest size: 380*508mm Largest size: 160*1500mm |

| 6 | PCB shape | Rectangular Round Slots and Cutouts Complex and Irregular |

| 7 | PCB type | Rigid PCB Metal Core PCB Flexible PCB, Rgid-Flex PCB |

| 8 | Assembly process | Lead-Free (RoHS) |

| 9 | Production Time | 9-15 Working Days for Prototype 16-21 Working Days for Medium Volume 22-31 Working Days for Mass Production |

Copyright © 2009 - 2024 SUNGHOM TECHNOLOGY LIMITED | All Rights Reserved | Powered by SkyWeb